• For generic or budget oriented projects C frame presses are the most suitable.

• Other models may be used as well as custom solutions that are designed for the specific need of the process.

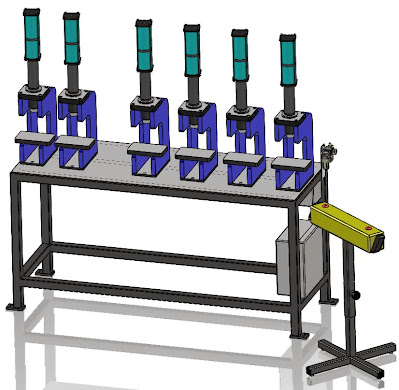

• Modular presses are excellent to process aluminum extrusions with great lengths and multiple holes, slots, etc. to be punched at once at the full length of the extrusion.

• The process time is minimal, compared to conventional methods where individual holes had to be drilled or punched one at a time. The quality is more predictable and repeatable.

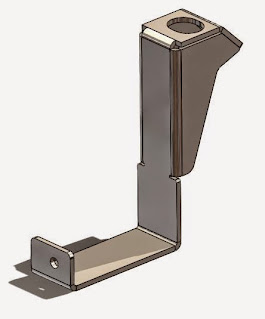

• Multi axis power unit mounts are available to work horizontally or in an angle within the same machine.

• Drilling units can be also used to work along with the cylinders.

• Extrusion positioning and clamping can be automated. The function can be monitored by a PLC to ensure trouble free operation and keep the required quality under control.

• Safety devices may be installed, depending of your company or government requirements.